Understanding the Capacitor Bench Grinder Wiring Diagram is essential for anyone working with bench grinders, especially those that feature a capacitor. This diagram acts as a blueprint, detailing how the electrical components, particularly the capacitor, are interconnected to ensure the grinder operates safely and efficiently. A clear grasp of the Capacitor Bench Grinder Wiring Diagram empowers users to perform maintenance, troubleshoot issues, and even undertake minor repairs.

What is a Capacitor Bench Grinder Wiring Diagram and How is it Used?

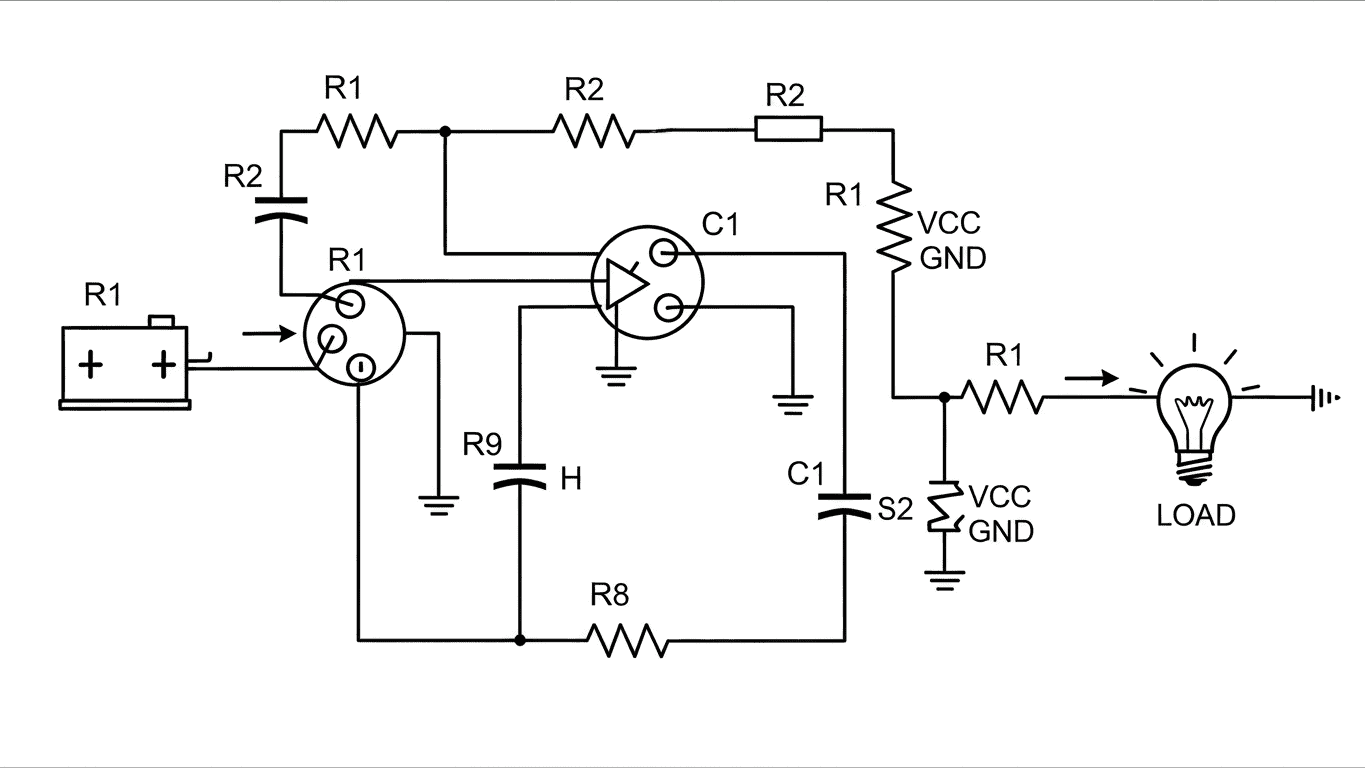

A Capacitor Bench Grinder Wiring Diagram is a schematic representation that illustrates the electrical connections within a bench grinder that utilizes a capacitor. This capacitor plays a crucial role, often acting as a starting capacitor to provide the initial torque needed to get the motor spinning, or as a running capacitor to maintain smooth operation. Without the correct wiring, the motor might struggle to start, run at reduced power, or even overheat. The importance of following the Capacitor Bench Grinder Wiring Diagram cannot be overstated, as incorrect connections can lead to electrical hazards, damage to the grinder, and potential injury.

The diagram typically shows the flow of electricity from the power source through various components like switches, overload protectors, and the motor windings, with the capacitor integrated into the starting or running circuit. It uses standardized symbols to represent each electrical part. For instance:

- A simple line might represent a wire.

- A circle with an 'M' inside often denotes the motor.

- A symbol resembling two parallel plates indicates a capacitor.

- A zigzag line can represent a switch.

These diagrams are invaluable for electricians and DIY enthusiasts alike. They provide a visual guide for:

- Installation: Ensuring all components are connected in the correct sequence and polarity.

- Troubleshooting: Identifying faulty components or broken connections when the grinder isn't performing as expected.

- Repair: Guiding the replacement of damaged parts, such as a burnt-out capacitor or a faulty switch.

Different types of bench grinders might have slightly varied wiring configurations, but the fundamental principles shown in the Capacitor Bench Grinder Wiring Diagram remain consistent. For example, a single-phase AC motor commonly uses a starting capacitor. The diagram would then show this capacitor connected in parallel with the starting winding of the motor, and a centrifugal switch would disconnect it once the motor reaches a certain speed. Understanding these specifics, as laid out in the diagram, is key to successful maintenance.

To accurately understand and utilize your specific bench grinder's electrical setup, refer to the detailed guide found in the documentation provided by the manufacturer. This guide will contain the precise Capacitor Bench Grinder Wiring Diagram tailored to your model.