Understanding a Capacitor Compressor Wiring Diagram Single Phase is essential for anyone dealing with single-phase electric motors, particularly in applications like refrigerators, air conditioners, and pumps. This diagram provides a visual guide to how the motor, capacitor, and power supply are connected to ensure the compressor starts and runs efficiently. A properly interpreted Capacitor Compressor Wiring Diagram Single Phase can be your best friend when troubleshooting or performing maintenance.

What is a Capacitor Compressor Wiring Diagram Single Phase?

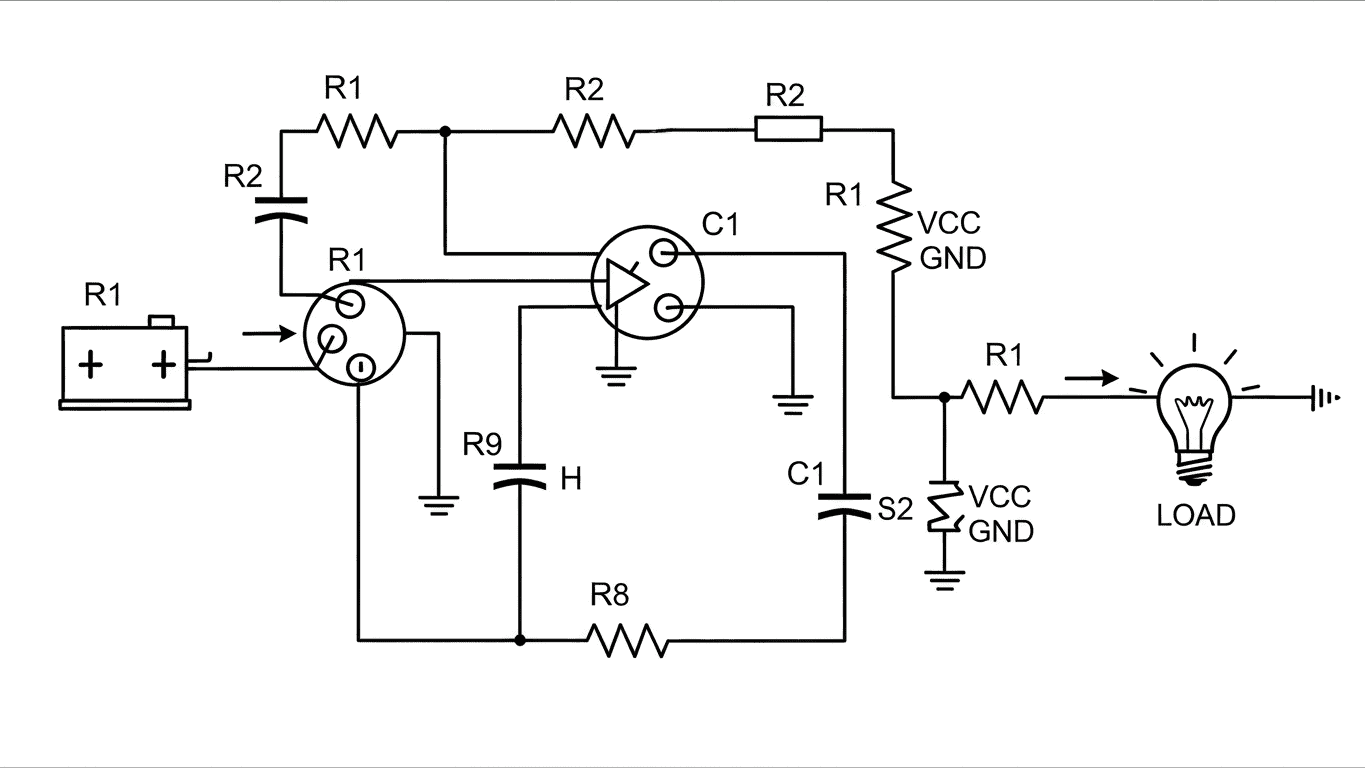

A Capacitor Compressor Wiring Diagram Single Phase illustrates the electrical connections for a single-phase AC motor that utilizes a capacitor to aid in starting. Single-phase power, commonly found in homes and small businesses, has a single alternating current wave. While this power is sufficient for many devices, single-phase motors require a little extra help to overcome their inherent inertia and begin rotating. This is where the capacitor comes into play. It temporarily creates a phase shift in the electrical current, essentially giving the motor the "push" it needs to start spinning.

These diagrams are crucial because they map out the flow of electricity and the role of each component. They show how the main winding and the start winding of the motor are connected, and how the capacitor is wired in series with the start winding. Here are some key components typically found in such a diagram:

- Motor Windings: The main winding handles the continuous operation, while the start winding, along with the capacitor, assists in initiating rotation.

- Capacitor: This is the key component for starting. It stores electrical energy and releases it to create a magnetic field that helps the rotor turn.

- Centrifugal Switch (or Relay): This device is often included to disconnect the start winding and capacitor once the motor reaches a certain speed, preventing damage and improving efficiency.

The importance of correctly understanding and following a Capacitor Compressor Wiring Diagram Single Phase cannot be overstated for safety and operational effectiveness. Incorrect wiring can lead to motor failure, fire hazards, or inefficient operation. For instance, a capacitor that is too large or too small for the motor will either cause the motor to overheat or fail to start properly.

Below is a simplified representation of how the components might be laid out, though actual diagrams can vary in complexity and detail:

| Component | Connection Point |

|---|---|

| Power Supply (L, N) | Main Motor Terminal, Capacitor Circuit |

| Capacitor | In series with Start Winding, connected to Main Winding |

| Start Winding | Connected to Capacitor and then to Power |

| Main Winding | Connected directly to Power |

| Centrifugal Switch | In series with Start Winding and Capacitor |

By studying the Capacitor Compressor Wiring Diagram Single Phase, you can identify the specific terminals for each connection, understand the sequence of operations, and ensure that all components are wired in their correct positions. This is especially helpful when replacing a faulty capacitor or motor, as the diagram serves as a blueprint for reassembly. Whether you are a DIY enthusiast or a professional technician, a good understanding of these diagrams is fundamental.

To gain a deeper understanding and to see specific examples, you should refer to the detailed diagrams provided by the equipment manufacturer. These official sources offer the most accurate and up-to-date information for your particular application.