A Can Wiring Diagram is an essential tool for anyone working with systems that utilize the Controller Area Network (CAN) bus. Whether you're a mechanic diagnosing a vehicle issue, an engineer designing an embedded system, or simply a hobbyist exploring automotive electronics, understanding a Can Wiring Diagram is key to successful troubleshooting and implementation. This guide will break down what these diagrams are and how they are used, making complex connections clear.

What is a Can Wiring Diagram and How Is It Used?

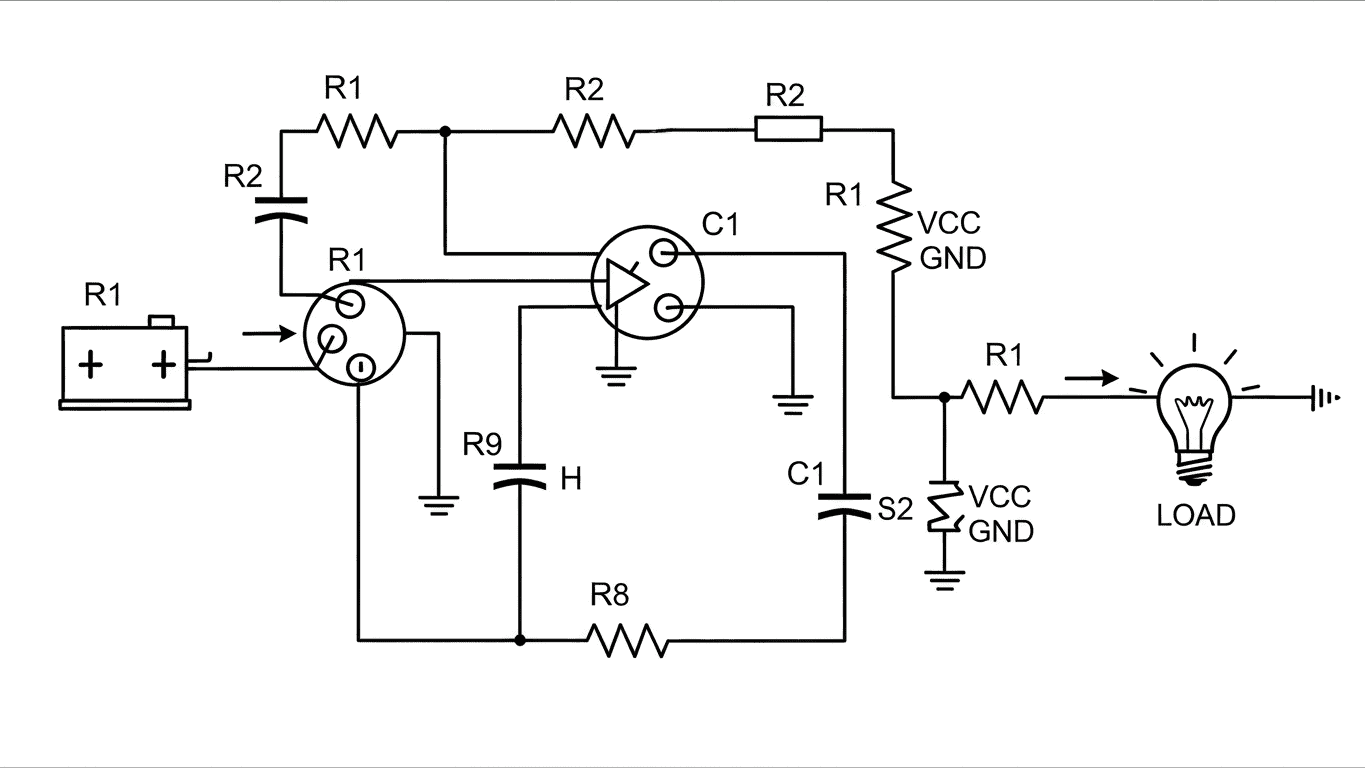

At its core, a Can Wiring Diagram is a visual representation of how the various components within a CAN bus network are interconnected. It's like a roadmap for electrical signals. The CAN bus is a robust communication protocol widely adopted in automotive, industrial, and aerospace applications due to its reliability and efficiency in transmitting data between microcontrollers and devices without a host computer. A Can Wiring Diagram shows the physical connections, including the wires, connectors, and the specific pins on each Electronic Control Unit (ECU) or device that are part of the CAN network. These diagrams are crucial for identifying correct pinouts, signal paths, and the overall topology of the network.

The primary purpose of a Can Wiring Diagram is to facilitate understanding and maintenance. For technicians, it's invaluable for diagnosing faults. If a particular ECU isn't communicating on the bus, the diagram helps them trace the wiring from that ECU to other nodes and to the main CAN bus lines (CAN High and CAN Low). They can check for breaks, shorts, or loose connections. Engineers use these diagrams during the design phase to ensure proper integration of new ECUs into an existing network, verifying that all connections are made according to the protocol's specifications. The information provided can be detailed, often including:

- The specific CAN bus lines (CAN_H, CAN_L)

- Power and ground connections for each ECU

- Termination resistors, which are vital for signal integrity

- Identification of each ECU or node on the bus

- Connector types and pin assignments

Understanding the layout and components depicted in a Can Wiring Diagram is paramount to preventing damage to sensitive electronics and ensuring the correct operation of the entire system . Without it, troubleshooting becomes guesswork, leading to wasted time and potential component failures. For example, a simple mistake like connecting a CAN High wire to a CAN Low pin on a different device could disrupt the entire network or even damage the connected ECUs. A typical CAN bus network might include:

- Master ECUs (e.g., Engine Control Module)

- Slave ECUs (e.g., ABS Module, Body Control Module)

- Connectors and splices

- Bus termination resistors at each end of the bus

Here's a simplified example of what you might see represented:

| Device | CAN High Pin | CAN Low Pin |

|---|---|---|

| ECU A | Pin 12 | Pin 14 |

| ECU B | Pin 3 | Pin 5 |

To delve deeper into the specifics of your system's CAN connections and unlock the full potential of effective troubleshooting, refer to the detailed diagrams provided in your system's official service manual or technical documentation. These resources are your most accurate guide.