A Cdi Wiring Diagram is an essential tool for anyone working with internal combustion engines, particularly those found in motorcycles, scooters, and some smaller vehicles. Understanding a Cdi Wiring Diagram is key to diagnosing ignition problems and ensuring your engine runs smoothly. This diagram visually represents the electrical connections within the Capacitive Discharge Ignition (CDI) system, a popular type of ignition used for its reliability and simplicity.

What is a Cdi Wiring Diagram and How Does It Work?

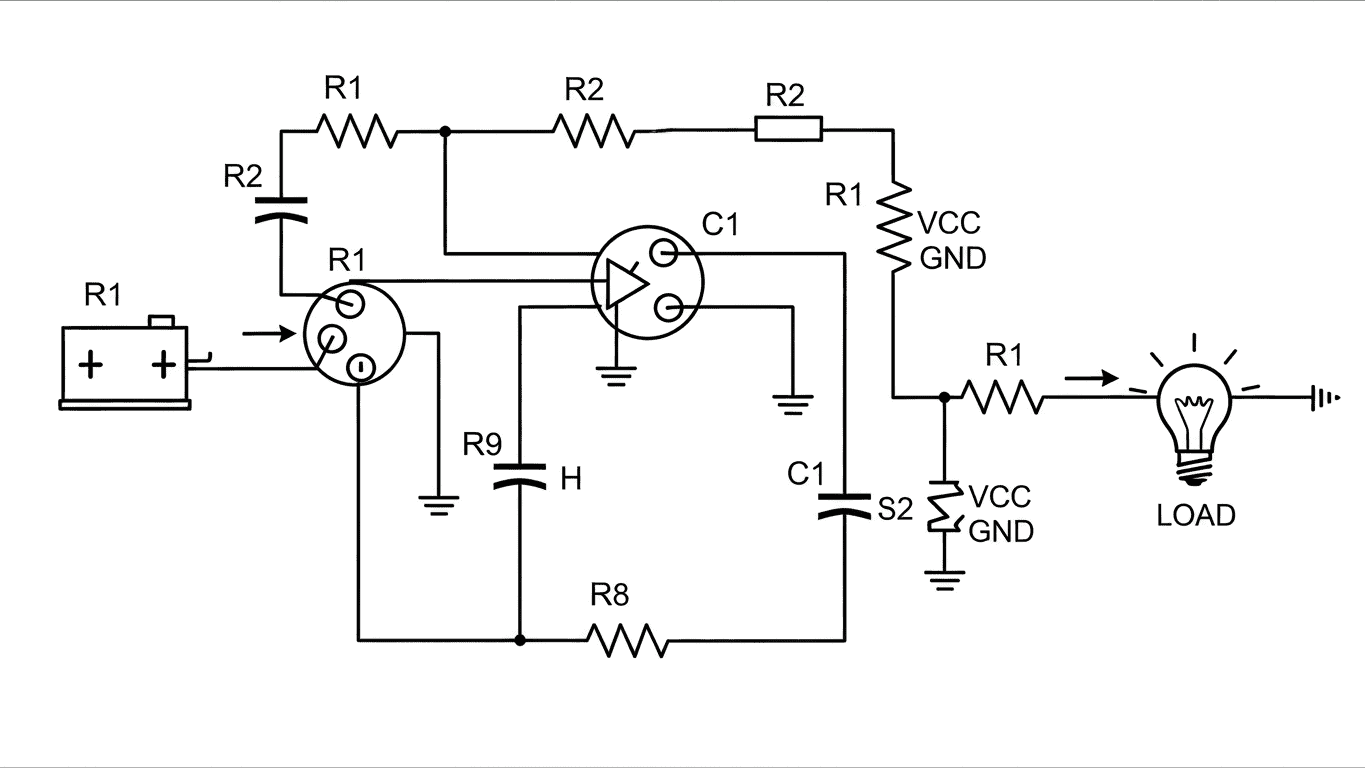

At its core, a Cdi Wiring Diagram is a schematic that illustrates how the various electrical components of a CDI system are interconnected. This system is responsible for generating the high voltage spark that ignites the fuel-air mixture in your engine's combustion chamber. The diagram shows the flow of electricity from the power source, through the CDI unit itself, and to the ignition coil and spark plug. Understanding this flow is crucial for troubleshooting any ignition-related issues.

The CDI unit is the brain of the ignition system. It receives a low-voltage signal from the engine's stator, typically timed by a pickup coil. This signal tells the CDI when to fire. The CDI then charges a capacitor with a high voltage. When the signal indicates it's time for a spark, the CDI discharges the capacitor's energy very rapidly into the ignition coil. This sudden surge of energy in the coil creates the extremely high voltage necessary to jump the gap on the spark plug, thus igniting the fuel. A Cdi Wiring Diagram will typically show:

- The stator and its connections

- The CDI unit and its terminals

- The ignition coil

- The kill switch or engine stop circuit

- The power source (often AC from the stator or DC from a battery)

When you encounter a problem with your engine not starting or running poorly, a Cdi Wiring Diagram becomes your roadmap. By following the connections on the diagram, you can systematically test each component and wire. For instance, you might check for continuity in the wiring harness, verify that the stator is producing the correct voltage, or ensure the CDI unit is receiving and sending the appropriate signals. A basic Cdi Wiring Diagram might look something like this:

| Component | Typical Connection Point |

|---|---|

| Stator Output | CDI Input (Signal/Charge) |

| CDI Output | Ignition Coil (Primary) |

| Kill Switch | CDI Ground/Signal Input |

If you're dealing with ignition problems, it's vital to consult the specific Cdi Wiring Diagram for your vehicle's make and model. Generic diagrams can offer a general understanding, but variations exist between manufacturers and engine types.

Don't let a faulty ignition system keep you grounded. By referencing the specific Cdi Wiring Diagram for your vehicle, you can gain the knowledge to diagnose and potentially repair the problem yourself. The detailed schematics provided in the following section will be your invaluable guide.