A Camshaft Sensor Wiring Diagram is a crucial piece of information for anyone looking to understand, diagnose, or repair the engine management system of a vehicle. This diagram essentially shows how the camshaft position sensor, a vital component in modern engines, is electrically connected to the rest of the car's computer system. Without a clear understanding of this Camshaft Sensor Wiring Diagram, troubleshooting engine issues related to timing and fuel injection can be a daunting task.

The Role and Function of the Camshaft Sensor Wiring Diagram

The camshaft position sensor (CMP) plays a critical role in an internal combustion engine. It tells the engine control module (ECM) or powertrain control module (PCM) the exact position of the camshaft. This information is used in conjunction with data from the crankshaft position sensor to determine when each cylinder is on its power stroke. This precise timing allows the ECM to optimize fuel injection and ignition timing for maximum performance, fuel efficiency, and reduced emissions. The accurate functioning of the Camshaft Sensor Wiring Diagram directly impacts the engine's ability to run smoothly and efficiently.

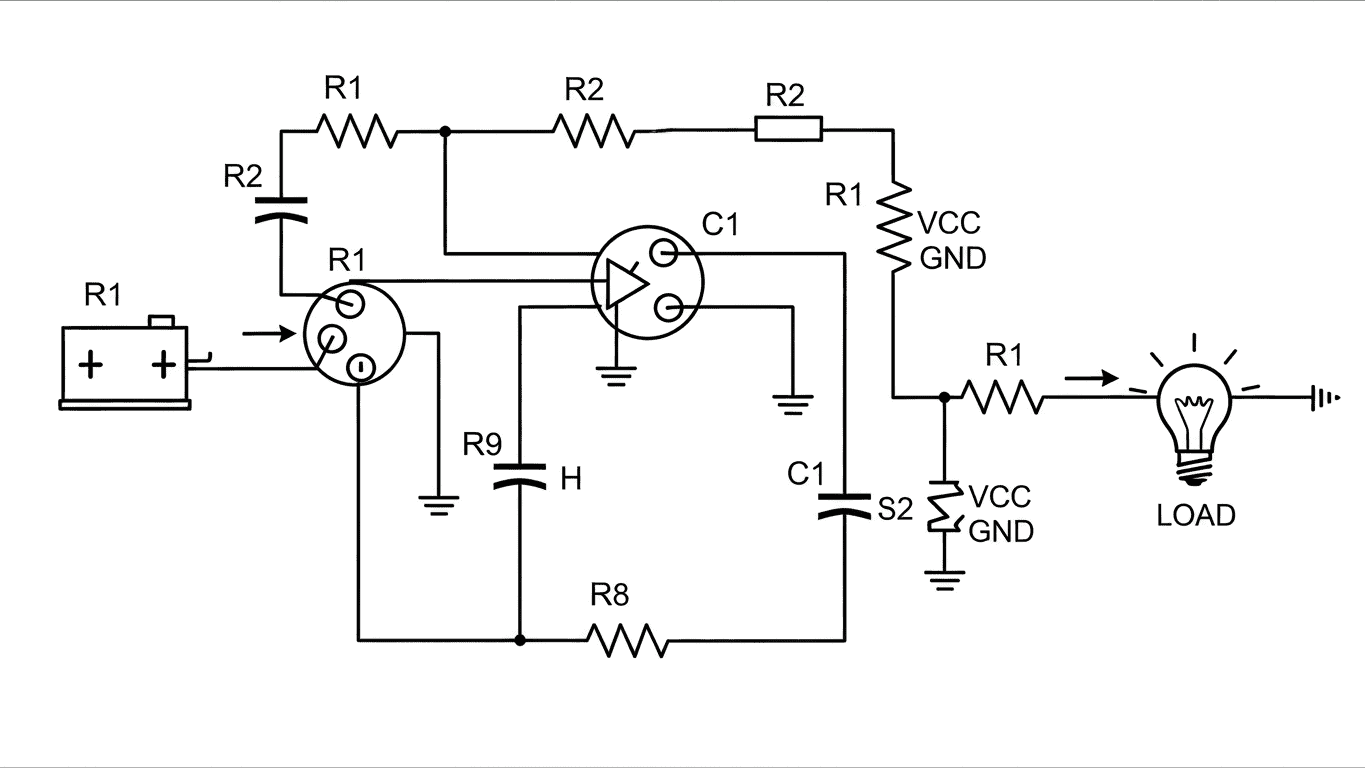

When you encounter a Camshaft Sensor Wiring Diagram, you'll typically see a representation of the sensor itself, usually with three pins or connectors. Each of these pins will be connected to a specific wire, and these wires will lead to different parts of the vehicle's wiring harness and ultimately to the ECM. The diagram will illustrate the color of each wire and the corresponding pin or terminal it connects to on both the sensor and the ECM. This detailed mapping is essential for:

- Identifying the power, ground, and signal wires for the camshaft sensor.

- Tracing the path of the electrical signal from the sensor to the control module.

- Diagnosing faults such as open circuits, short circuits, or poor connections.

Understanding the Camshaft Sensor Wiring Diagram also helps in identifying potential issues that could arise from damaged wiring. For instance, a frayed wire could cause an intermittent signal, leading to engine misfires or a rough idle. Conversely, a completely severed wire would result in the ECM not receiving any camshaft position information, often causing the engine to stall or fail to start. A typical camshaft sensor has three wires, each with a distinct purpose:

| Wire Function | Typical Description |

|---|---|

| Power | Provides voltage to the sensor. |

| Ground | Completes the electrical circuit. |

| Signal | Transmits the camshaft position data to the ECM. |

A reliable Camshaft Sensor Wiring Diagram will clearly label these functions and their corresponding wire colors, providing a roadmap for any electrical diagnosis.

To ensure you have the most accurate information for your specific vehicle, it's highly recommended to consult the specific Camshaft Sensor Wiring Diagram for your make, model, and year. This will ensure that you are working with the correct wire colors and pinouts, avoiding potential mistakes that could lead to further damage.