Understanding the Cam 3 Wire Crank Sensor Wiring Diagram is crucial for anyone working on modern automotive engines. This diagram provides a visual guide to how the engine control module (ECM) receives vital information about the crankshaft's position and speed. Accurately interpreting this Cam 3 Wire Crank Sensor Wiring Diagram ensures proper engine function, ignition timing, and fuel injection. Without a clear understanding of the Cam 3 Wire Crank Sensor Wiring Diagram, diagnosing and repairing related issues can be a complex and frustrating task.

The Crucial Role of the Cam 3 Wire Crank Sensor Wiring Diagram

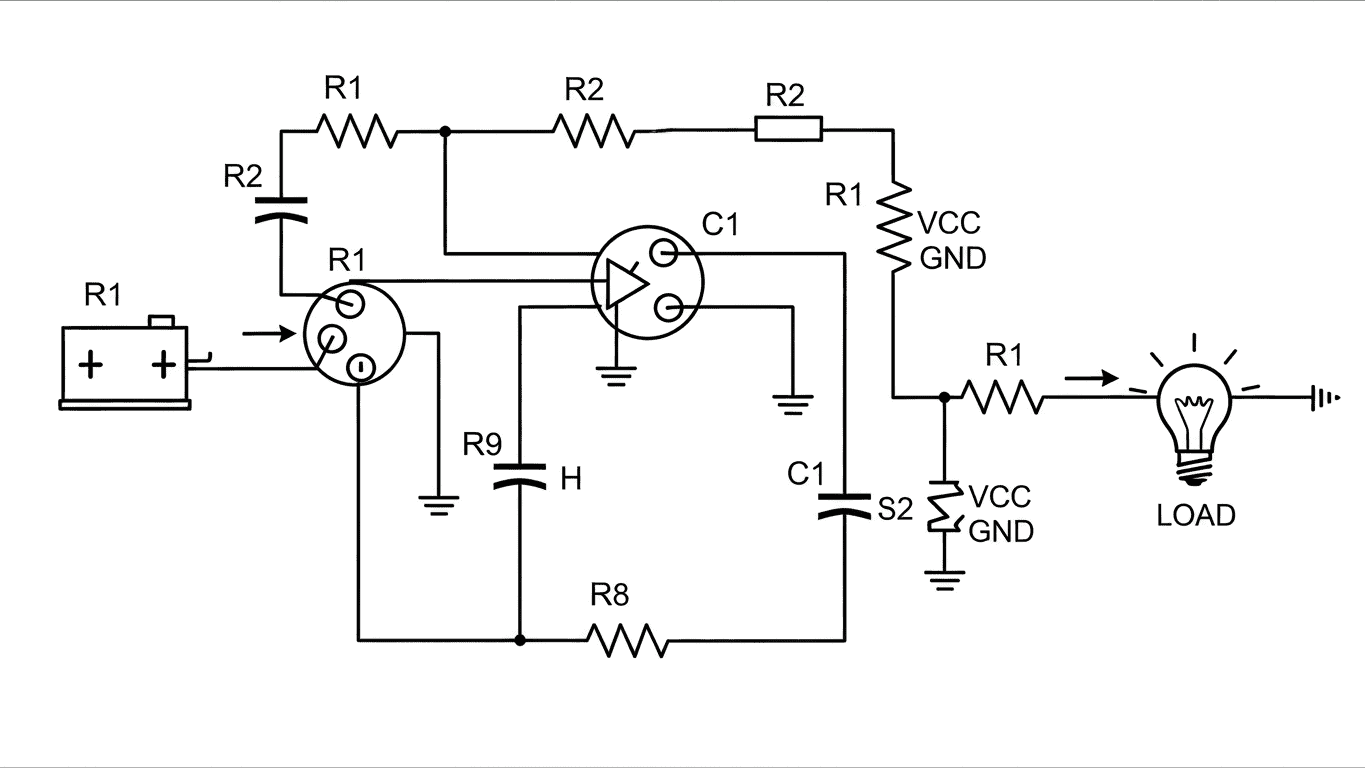

A 3-wire crankshaft position sensor is a critical component in an engine's ignition and fuel management system. It works by generating a signal that tells the engine control module (ECM) the exact rotational speed and position of the crankshaft. This information is essential for calculating the precise moment to fire the spark plugs and inject fuel. The wiring diagram for this sensor, the Cam 3 Wire Crank Sensor Wiring Diagram, illustrates the connections between the sensor, the ECM, and the vehicle's power supply. Essentially, it's the blueprint that ensures these vital signals are transmitted correctly.

The three wires on a typical crankshaft position sensor usually serve distinct purposes:

- Power Supply: This wire provides the necessary voltage for the sensor to operate.

- Ground: This wire ensures a complete circuit for the sensor's signal.

- Signal Output: This wire carries the data from the sensor to the ECM.

The type of sensor can influence the specifics of the Cam 3 Wire Crank Sensor Wiring Diagram. For example, a Hall effect sensor will have a slightly different wiring configuration compared to a variable reluctance sensor. Each type relies on the correct connections as outlined in the respective Cam 3 Wire Crank Sensor Wiring Diagram to function accurately. The proper functioning of the entire engine relies on the integrity of these connections.

Without a correctly functioning crankshaft position sensor and its associated wiring, the ECM would be "blind" to the engine's rotation. This would lead to:

- No start condition.

- Rough idling.

- Misfires.

- Poor fuel economy.

- Illumination of the check engine light.

A thorough examination of the Cam 3 Wire Crank Sensor Wiring Diagram is the first step in diagnosing any problems related to the crankshaft position sensor. It allows technicians to trace the wires, check for continuity, and verify power and ground connections. Below is a simplified representation of what you might find in a typical Cam 3 Wire Crank Sensor Wiring Diagram:

| Wire Color (Example) | Function | ECM Pin (Example) |

|---|---|---|

| Red | Power Supply | A |

| Black | Ground | B |

| White | Signal Output | C |

For the most accurate and vehicle-specific information, always refer to the official Cam 3 Wire Crank Sensor Wiring Diagram provided by the vehicle manufacturer or a reputable automotive repair manual. The information presented here is a general overview and may not perfectly match every application. Utilizing the precise diagram for your specific vehicle is essential for successful diagnostics and repairs.

To ensure you have the exact specifications for your vehicle's Cam 3 Wire Crank Sensor Wiring Diagram, please consult the detailed service manual for your make and model.