Understanding a Brushless Motor Controller Wiring Diagram is crucial for anyone working with or looking to implement brushless DC (BLDC) motors. These diagrams act as the blueprint, illustrating how to correctly connect the motor, the controller, and the power source to ensure proper operation and prevent damage. A clear grasp of the Brushless Motor Controller Wiring Diagram simplifies the setup process and enhances system reliability.

Demystifying the Brushless Motor Controller Wiring Diagram

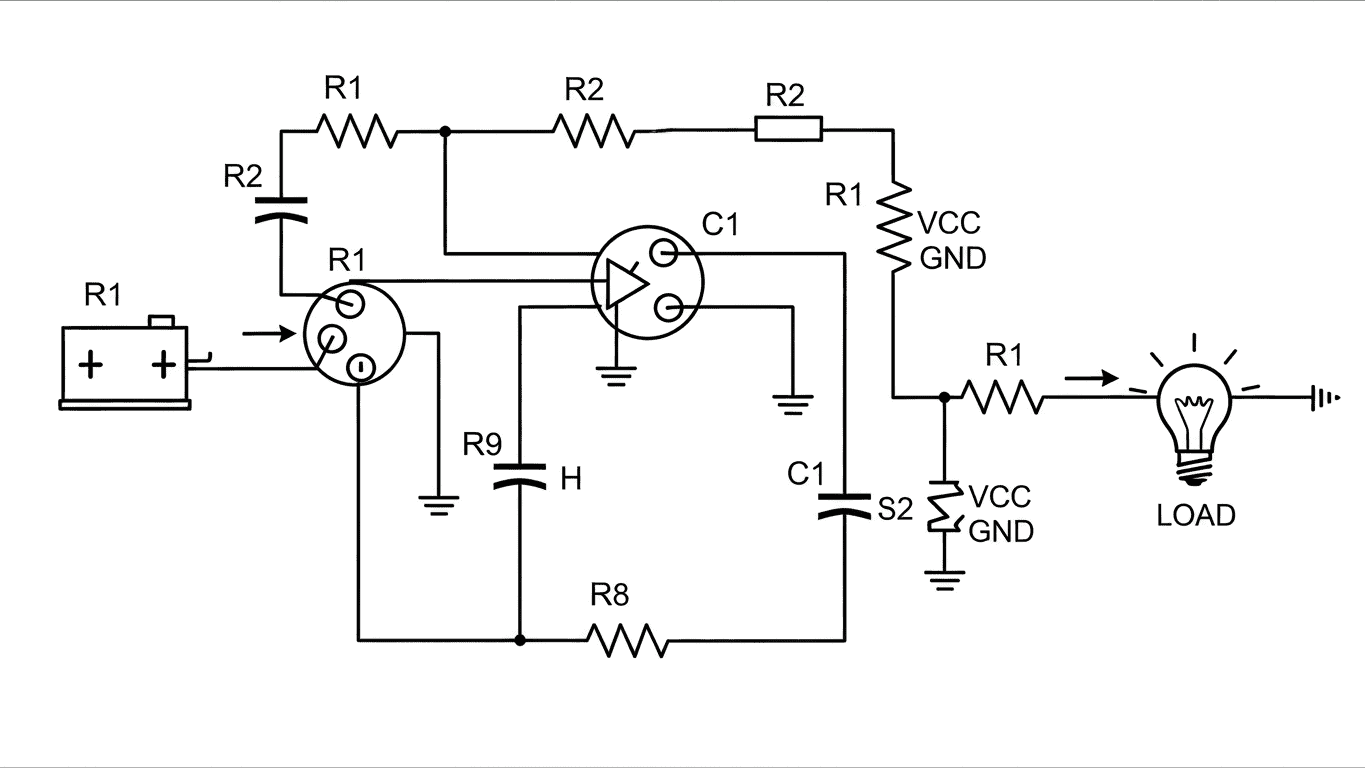

At its core, a Brushless Motor Controller Wiring Diagram shows the electrical pathways between the key components of a BLDC motor system. Unlike brushed motors that use physical brushes to switch current direction, BLDC motors rely on electronic commutation managed by a controller. The diagram details the connections for the motor's phases (typically three), the power input, and any control signals. Without a proper Brushless Motor Controller Wiring Diagram, connecting these components can be a complex and potentially damaging undertaking.

The purpose of the controller, as depicted in the wiring diagram, is to precisely control the timing and sequence of electrical pulses sent to the motor's windings. This electronic commutation is what allows BLDC motors to achieve higher efficiency, longer lifespan, and quieter operation compared to their brushed counterparts. Key elements you'll typically find on a Brushless Motor Controller Wiring Diagram include:

- Motor Phase Wires: These are the primary connections between the controller and the motor windings. They are often color-coded for ease of identification.

- Power Input: This shows where the battery or power supply connects to the controller. It will usually be labeled with positive (+) and negative (-) terminals.

- Sensor Connections (Optional): Many BLDC motors use Hall effect sensors to provide feedback on rotor position. The diagram will show how these sensors connect to the controller.

- Control Signals: This can include connections for throttle input (e.g., from a potentiometer or receiver), direction control, or other advanced features.

A thorough understanding of the Brushless Motor Controller Wiring Diagram is essential for several reasons. Firstly, it ensures that the motor receives the correct power and signals, allowing it to spin smoothly and efficiently. Incorrect wiring can lead to the motor not spinning at all, spinning erratically, or even burning out the controller or motor. Secondly, following the diagram helps in troubleshooting any issues that may arise. By verifying each connection against the diagram, you can quickly identify and rectify problems. The ability to interpret and apply a Brushless Motor Controller Wiring Diagram is fundamental to successful BLDC motor integration.

To help you visualize these connections, here's a simplified representation of common wiring elements found in a Brushless Motor Controller Wiring Diagram:

| Component | Typical Connections |

|---|---|

| Controller | Motor Phase Wires (A, B, C) |

| Power Input (+, -) | |

| Hall Sensor Inputs (if applicable) | |

| Control Input (e.g., PWM signal) | |

| Motor | Motor Phase Wires (A, B, C) |

| Power Source | Power Input terminals on controller |

Now that you have a foundational understanding of what a Brushless Motor Controller Wiring Diagram entails, it's time to put this knowledge into practice. The section below provides a comprehensive resource for specific diagrams. Refer to it to select the correct wiring schematic for your application and ensure a successful and safe setup.