Understanding your boat's systems is key to safe and efficient operation. Among these vital components, the Boat Trim Gauge Wiring Diagram plays a significant role. This diagram serves as the blueprint for how your trim gauge receives information and communicates with your boat's trim system, allowing you to monitor and adjust your engine's trim angle. Without a clear grasp of the Boat Trim Gauge Wiring Diagram, troubleshooting or even understanding basic trim functionality can be challenging.

The Heart of Your Trim Control: Understanding the Boat Trim Gauge Wiring Diagram

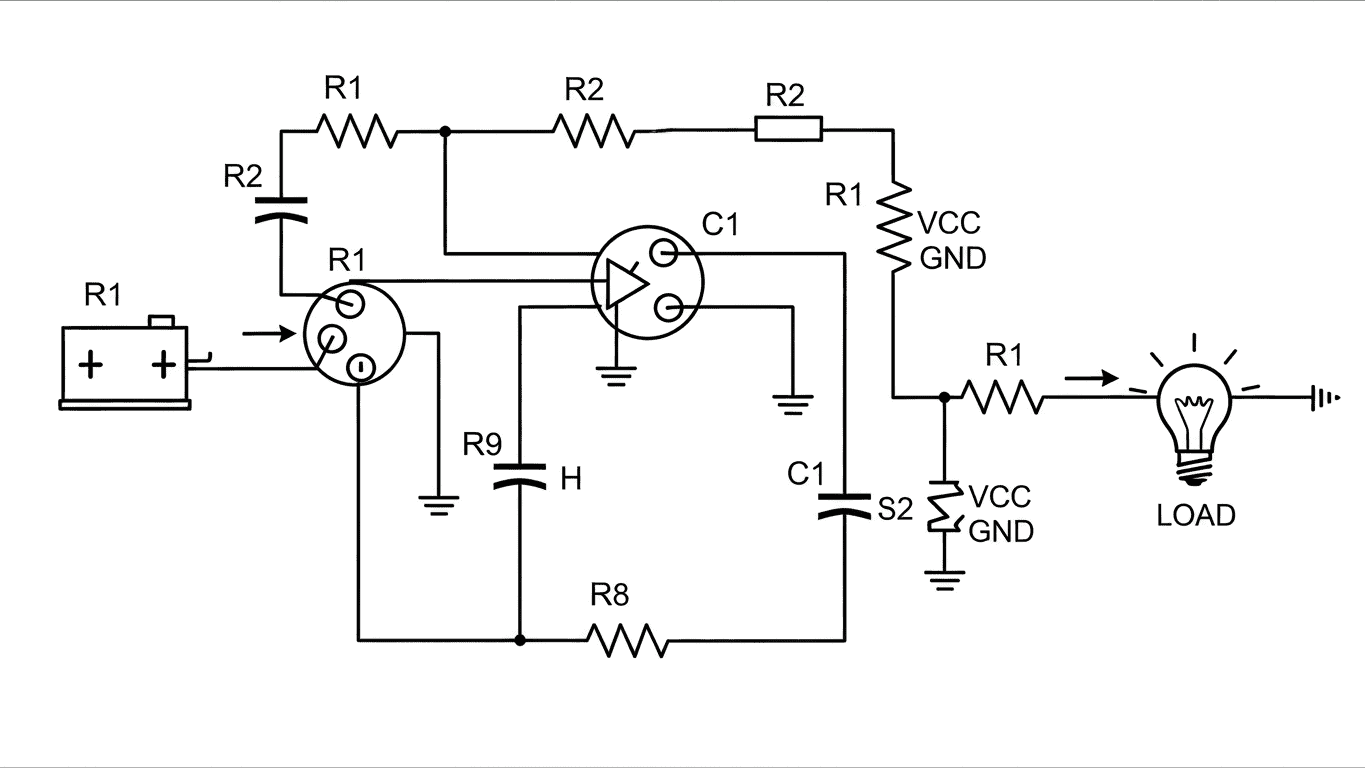

A Boat Trim Gauge Wiring Diagram is essentially a schematic that illustrates the electrical connections between your boat's trim sender (typically located on the outboard engine or stern drive) and the trim gauge itself, usually mounted on your dashboard. This diagram outlines which wires carry power, ground, and the signal from the sender to the gauge. By following this diagram, you can ensure that the electrical pathway is intact and functioning correctly, which is essential for accurate trim readings.

The trim gauge works by interpreting the resistance or voltage signals sent by the trim sender. The sender unit has a movable arm that corresponds to the physical angle of your engine or drive. As the trim angle changes, the sender's internal components adjust, altering the electrical signal. The Boat Trim Gauge Wiring Diagram shows how these signals are routed. Here's a breakdown of common elements you'll find:

- Power (Usually Red): This wire provides the necessary voltage for the gauge to operate.

- Ground (Usually Black): This wire completes the electrical circuit, returning power to the battery.

- Signal Wire (Often Yellow or Blue): This wire carries the variable signal from the trim sender to the gauge.

The importance of a properly functioning Boat Trim Gauge Wiring Diagram cannot be overstated. It not only allows you to optimize your boat's performance and fuel efficiency by adjusting the trim angle for different water conditions and speeds, but it also plays a role in safety. For instance, knowing your trim angle can help prevent porpoising (excessive bouncing) or cavitation (loss of propeller grip), both of which can be dangerous. The diagram is also your first step in diagnosing issues like a non-responsive gauge or erratic readings. Without it, you're essentially working blind when it comes to your trim system's electrical integrity.

To get started with understanding your specific trim gauge setup, we highly recommend consulting the detailed schematic provided in the next section.